- +86 19353265952

- [email protected]

- Shijiazhuang city

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

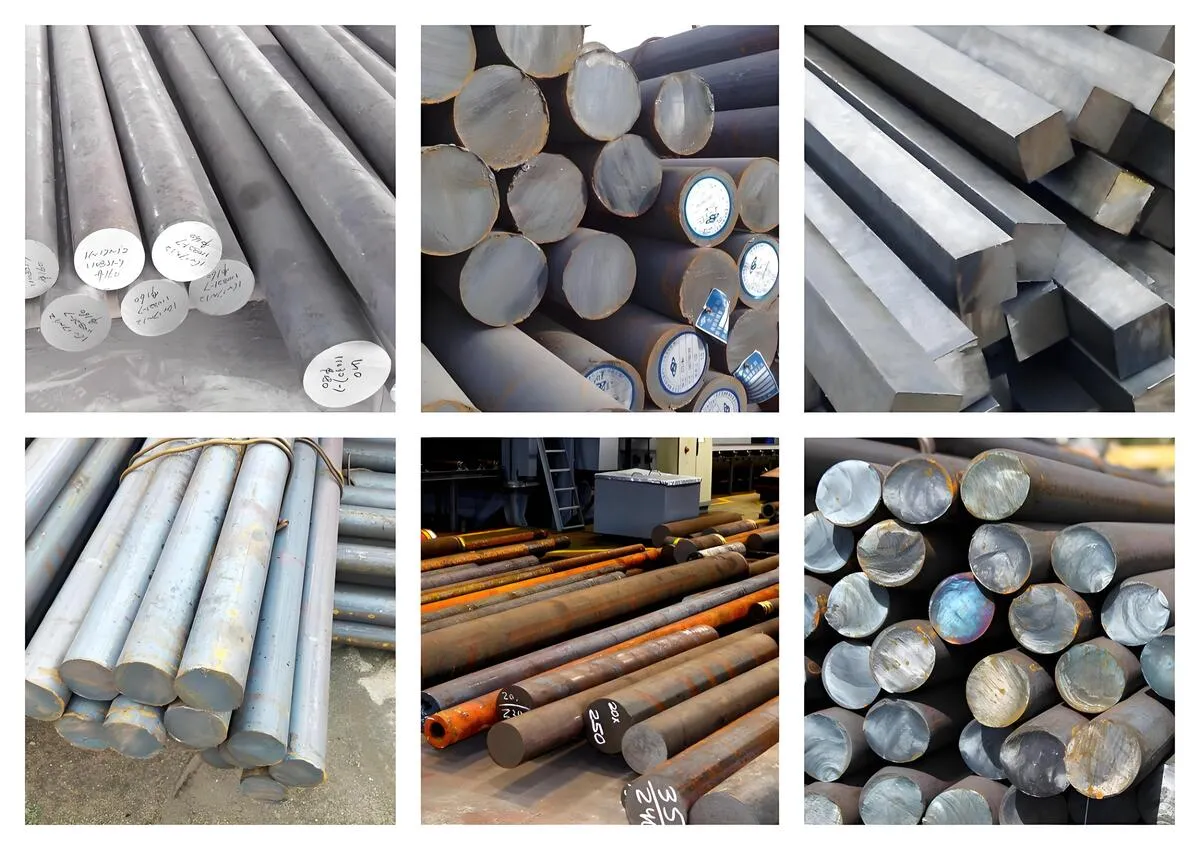

Carbon steel bars are rod-shaped materials processed from carbon steel. It has good mechanical properties, with moderate strength and hardness. Carbon steel bars are widely used in the machinery manufacturing industry and are often used to make shaft parts, bolts, gears, etc. In the construction field, they can also be used to strengthen the support of the structure. For example, the transmission shaft in a car engine may be processed from carbon steel bars to ensure the effective transmission of power.

Category: Carbon steel rod

Key word: Carbon steel rod

![]() Whatsapp :+86 19353265952

Whatsapp :+86 19353265952

![]() Email : [email protected]

Email : [email protected]

Carbon steel rod is a commonly used engineering material made of carbon steel, with various specifications and sizes. It is a round or other shaped bar made from carbon steel or alloy steel through rolling or forging processes. The carbon content is usually between 0.05% and 1.5%, which determines the mechanical and processing properties of carbon steel bars. The mechanical properties of carbon steel bars can be improved through heat treatment processes such as quenching and tempering. It also contains other elements such as manganese and silicon.

| Product Name | Carbon Steel Bar |

|---|---|

| Length | 3m-6m or as required |

| Diameter | 4mm-350mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled, Cold Drawn |

| Surface Treatment | Polished, primary according to customer requirement |

| Thickness tolerance | ±0.1mm |

| Material | Q345B,Q345C,Q345D,Q345E,Q390,Q390B,Q390C,Q390D,Q390E,Q420,Q420B,Q420C,Q420DQ420E,Q460,Q460D,Q500C,Q500D,Q500E,Q550C, Q550D,Q550E,Q620C,Q620D,Q620E,Q690A,Q690B,Q690C,Q690D,Q690E,Q690D,Q690C,Q890C,Q890D 16Mo3,16MnL,16MnR ,16Mng,16MnDR HG785D,S690QL,50MN |

| Application | It is mainly used to make structural parts such as car girder, beam, transmission shaft and car chassis parts, which can reduce the weight of the parts. |

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

| Capacity | 250,000 tons/year |

The packaging of carbon steel bars aims to protect the material from damage during transportation and storage. The packaging methods may include:

Loose: Short or small batches of carbon steel bars may be loose in pallets or containers.

Bundling: Long or large quantities of carbon steel bars may be bundled together for easy handling and counting.

Anti corrosion packaging: may include oiling or other anti-corrosion measures to protect carbon steel rods from corrosion.

Plastic packaging: Use plastic film or other materials to wrap carbon steel rods to prevent corrosion and contamination.

Proper packaging can ensure that carbon steel rods maintain their quality and performance during transportation and storage, while also facilitating loading, unloading, and handling.

Standard shipment package

plenty inventory

international standard

24 hours 7 days online

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.

14# Shenglung Building, Heping West road, Xinhua District, Shijiazhuang City, China

+(86) 19353265952

Don’t miss our future updates! Get Subscribed Today!