- +86 19353265952

- [email protected]

- Shijiazhuang city

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

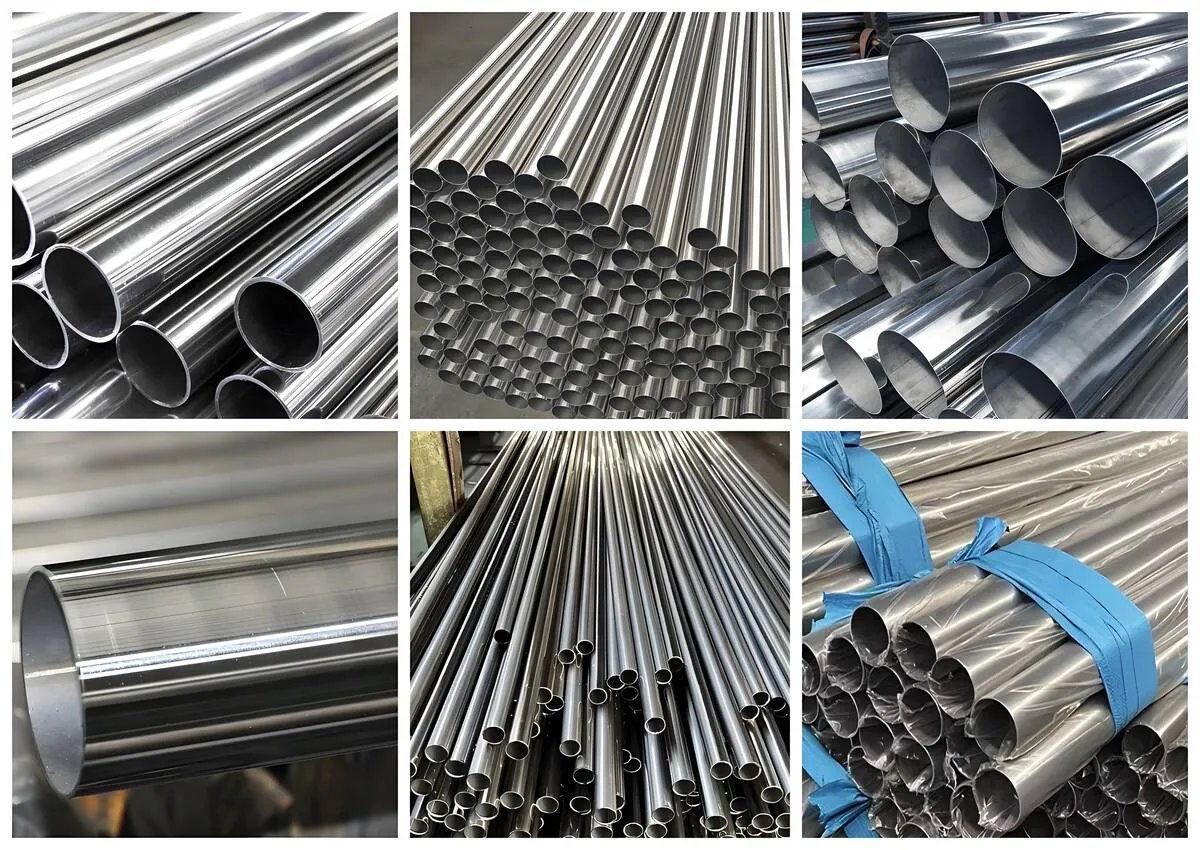

Stainless steel seamless pipe is a pipe made by seamless process. It has no weld, tight and uniform structure, high strength, good sealing and excellent corrosion resistance. It can work stably under harsh conditions such as high temperature and high pressure, and is widely used in petroleum, chemical, medical, machinery and many other fields. It is a high-quality pipeline material.

Category: Stainless steel seamless pipe

Key word: Stainless steel seamless pipe

![]() Whatsapp :+86 19353265952

Whatsapp :+86 19353265952

![]() Email : [email protected]

Email : [email protected]

1. Oil and gas industry: used to transport oil, natural gas and related products, capable of resisting corrosion and adapting to harsh working conditions.

2. Chemical industry: can transport a variety of corrosive chemicals and media.

3. Food and beverage industry: Due to its hygienic and corrosion-resistant properties, it is often used in piping systems for food processing, beverage production, and other processes.

4. Pharmaceutical industry: meets strict hygiene standards and can be used for fluid delivery in the pharmaceutical process.

5. Water supply and drainage system: used for urban water supply and drainage pipes.

6. Energy industry: For example, in facilities such as nuclear power plants, it is used to transport various media.

7. Marine engineering: can resist the corrosion of seawater, suitable for offshore platforms, ships, and other piping systems.

8. Paper industry: conveying chemical solutions, etc.

9. HVAC system: as a transmission pipe for hot water, steam, etc.

10. Electronics and semiconductor industries: used in some production environments with high purity requirements.

11. Automotive manufacturing: used in automotive exhaust systems, cooling systems, etc.

12. Industrial equipment manufacturing: fluid pipes in various mechanical equipment.

| Type: | stainless steel pipe | |

|---|---|---|

| Outer Diameter: | 6-2500mm, (3/8″-100″) | |

| Thickness: | 0.3-150mm,(SCH10-XXS) | |

| Length: | 2000mm, 2500mm, 3000mm, 5800mm, 6000mm,12000mm, etc |

|

| Standard: | ASTM,AISI,JIS,,GB, DIN,,EN | |

| Surface: | BA,2B,NO.1,NO.4,4K,HL,8K | |

| Application: | It is widely used in high-temperature and electric industry, medical devices, construction, chemistry, food industry, agriculture, and ship components. |

|

| It also applies to food and beverage packaging, kitchen supplies, trains, aircraft, conveyor belts, vehicles, bolts, nuts, springs, and screen mesh etc. |

||

| Certification: | ISO, SGS,BV | |

| Technique: | Cold Drawn Seamless Tube / Welded pipe | |

| Edge: | Mill Edge Slit Edge | |

| Quality: | SGS Inspection | |

| Grade (ASTM UNS) | 201,304,304L,321,316,316L, 317L,347H,309S,310S,904L, |

|

| S32205,2507,254SMOS, 32760,253MA,N08926 |

||

| Grade (EN) | 1.4301,1.4307,1.4541,1.4401,1.4404, 1.4571,1.4438,1.4539,1.4547 |

|

| 1.4529,1.4562,1.4410,1.4878, 1.4845,1.4828,1.4876,2.4858,2.4819 |

||

| Supply Ability: | 5000 Ton/Tons per Month | |

1. Density: usually around 7.93g/cm ³, with a relatively high density.

2. Melting point: with a high melting point, the specific value will vary depending on the specific composition of stainless steel.

3. Thermal conductivity: The thermal conductivity is relatively low, making it a good thermal insulation material.

4. Resistivity: High resistivity, with certain resistance characteristics.

5. Strength: It has high strength and can withstand greater pressure and tensile force.

6. Processability: It has good ductility and machinability, and can be made into pipes of different shapes by various processing methods.

7. Appearance: Smooth surface with metallic luster.

1. Corrosion resistance: These stainless steels all contain a certain amount of chromium element, which can form a dense chromium oxide protective film on the surface, making it have good corrosion resistance and can resist the erosion of various media. However, the corrosion resistance of different models of stainless steel in specific environments may vary. For example, 316 and 316L stainless steels have better corrosion resistance in environments containing chloride ions; 304L and 316L are low-carbon versions, which can reduce the risk of intergranular corrosion; 2205 and 2507 duplex stainless steels have higher strength and corrosion resistance; 310S stainless steel has excellent high temperature resistance and oxidation resistance.

2. Oxidation resistance: It can still maintain good oxidation resistance in high temperature environments.

3. Stability: Under normal conditions, the chemical properties are relatively stable, making it difficult to chemically react with other substances.

4. Cleanliness: The surface is relatively easy to clean, and it is not easy to breed bacteria and contaminants. It should be noted that although these stainless steels have good performance, corrosion or other chemical reactions may still occur in some extreme environments or specific media. In practical applications, it is necessary to select the appropriate type of stainless steel pipe according to the specific use environment and requirements to ensure its performance and service life. At the same time, the operation during processing and installation will also affect the performance of stainless steel pipes, and the  relevant specifications and standards should be followed for operation.

relevant specifications and standards should be followed for operation.

Standard shipment package

plenty inventory

international standard

24 hours 7 days online

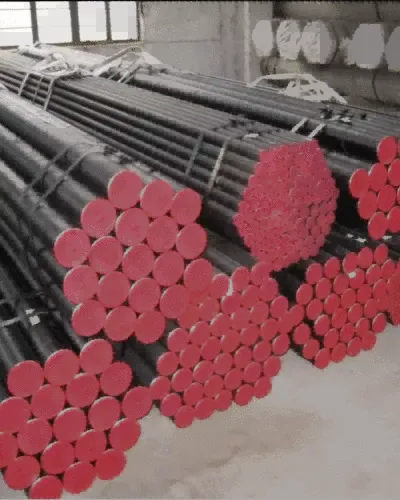

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.

14# Shenglung Building, Heping West road, Xinhua District, Shijiazhuang City, China

+(86) 19353265952

Don’t miss our future updates! Get Subscribed Today!