- +86 19353265952

- [email protected]

- Shijiazhuang city

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

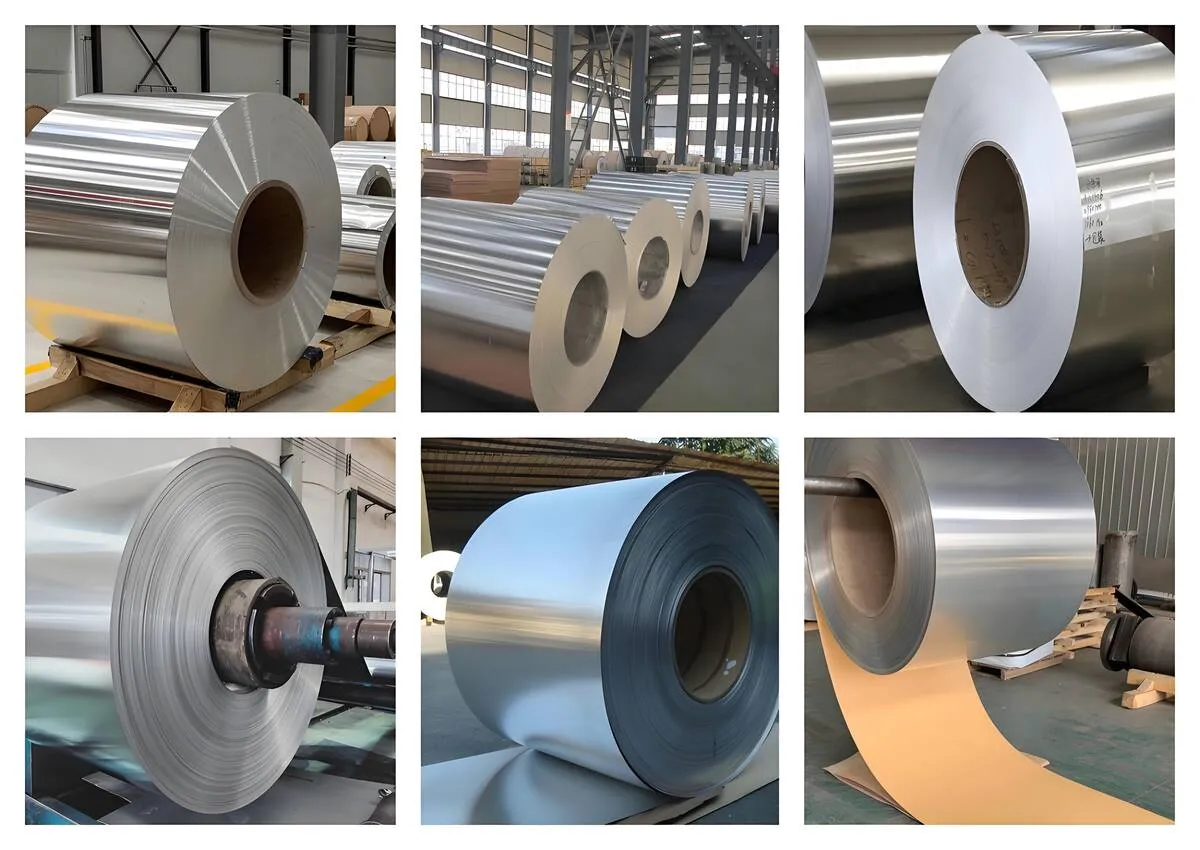

1100, 1060, 1050, 3003 aluminium alloy coils each have their own characteristics. 1100 has good corrosion resistance, 1060 has excellent electrical conductivity, 1050 has superior plasticity, and 3003 has slightly higher strength and corrosion resistance. They are widely used in electronics, construction, automobiles and other fields, have good processing performance, can meet diverse needs, and are commonly used aluminium alloy materials.

Category:1100 1060 1050 3003 Aluminum Coil

Key word: 1100 1060 1050 3003 Aluminum Coil

![]() Whatsapp :+86 19353265952

Whatsapp :+86 19353265952

![]() Email : [email protected]

Email : [email protected]

1100 aluminum alloy coil: – It has good corrosion resistance and processability, and is often used in chemical equipment, food industry equipment, heat sinks, nameplates, kitchen utensils, etc.

1060 aluminum alloy coil: – Good electrical conductivity, mainly used in conductors, capacitors, evaporators, decorative parts, etc.

1050 aluminum alloy coil: – often used in chemical instruments, sheet metal parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, etc.

3003 aluminum alloy coil: – slightly stronger than the 1100 series, with good corrosion resistance and formability, and is mostly used in building materials, automobile manufacturing (such as automobile radiators, fuel tanks), cookware, cans, etc.

| Product Name | aluminum coil |

|---|---|

| Capacity | 1000 tons/month |

| Certifications | ISO 9001 |

| Material | 1000, 2000, 3000, 4000, 5000, 6000series a) 1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc. b) 2000 Series: 2014, 2024, etc. c) 3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc. d) 4000 Series: 4045, 4047, 4343, etc. e) 5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5454, 5754, 5A06, etc. f) 6000 Series: 6061, 6063, 6082, 6A02, etc. |

| Thickness | 0.3-14mm |

| Width | 50-2000 mm |

| Coil Weight | 2-6 tons |

| Payment | 30% despoit in advance,70% balance before delivery |

Physical properties: – Low density, close to 2700kg/m ³; – Good ductility and formability; – Good weldability; – Good electrical and thermal conductivity. Chemical properties: – Aluminum content reaches 99.0%; – Contains a small amount of silicon, copper, zinc, manganese and other elements.

Physical properties: – low density; – high plasticity; – good electrical and thermal conductivity.

Chemical properties: – High aluminum content, usually up to 99.6%; – Less impurity elements such as silicon, copper, zinc, and manganese.

Physical properties: – relatively small density; – good plasticity, can be rolled into thin plates and foils; – has certain electrical and thermal conductivity.

Chemical properties: – contains not less than 99.5% aluminum; – contains trace amounts of silicon, copper, magnesium, zinc, manganese, titanium, vanadium, iron and other elements.

Physical properties: – low strength, but slightly higher than industrial pure aluminum; – improved mechanical properties after cold working; – high plasticity in the annealed state; – good corrosion resistance; – good weldability, but poor machinability.

Chemical properties: – It belongs to aluminum-manganese alloys; – It is mainly composed of aluminum and contains a certain amount of manganese.

Standard shipment package

plenty inventory

international standard

24 hours 7 days online

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.

14# Shenglung Building, Heping West road, Xinhua District, Shijiazhuang City, China

+(86) 19353265952

Don’t miss our future updates! Get Subscribed Today!