- +86 19353265952

- [email protected]

- Shijiazhuang city

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

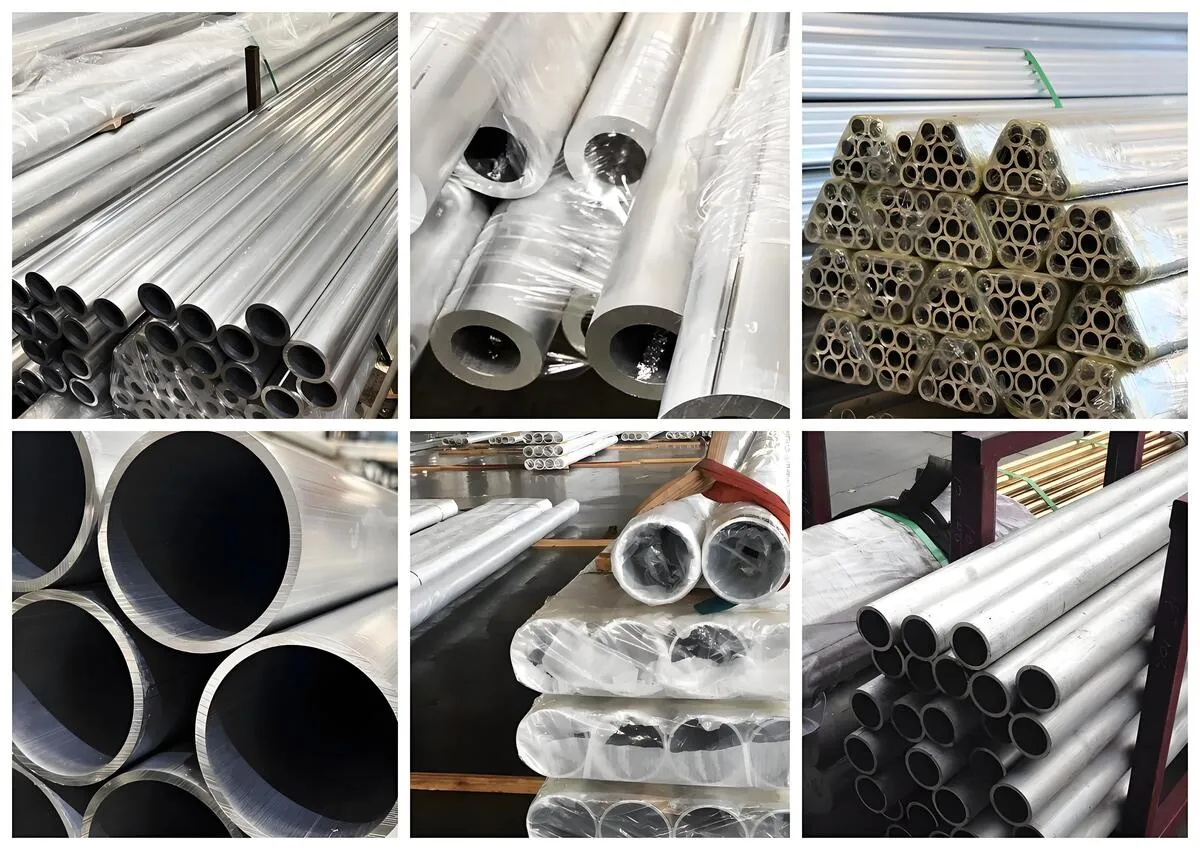

6063 aluminum alloy tube is a commonly used aluminum alloy material. It has good plasticity, corrosion resistance and machinability. It is often used in construction, industry, automobile and other fields to manufacture frames, pipes, etc. The composition includes magnesium, silicon, etc., with moderate strength and reasonable price. It is an ideal choice for many engineering and manufacturing projects.

Category: 6063 Aluminum Tube

Key word: 6063 Aluminum Tube

![]() Whatsapp :+86 19353265952

Whatsapp :+86 19353265952

![]() Email : [email protected]

Email : [email protected]

1. Construction field: It can be used to make structural parts such as doors and windows, curtain walls, etc. Its high strength and good corrosion resistance can meet the requirements of long-term use of buildings.

2. Industrial field: It is commonly used in the manufacture of various frame structures, such as shelves, brackets, industrial automation equipment, factory and office workbenches, ladders, etc.; It can also be used as aluminum profile wiring frames, workshop material turnover vehicles, automation equipment cabinets, aluminum alloy shelves, aluminum profile workshop lockers, belt conveyor lines, aluminum profile maintenance ladders, anti-static workbenches, chassis cabinets, robot fences, equipment protective covers, etc.

3. Automotive field: Manufacturing car parts such as body, suspension system, which helps to reduce the weight of the vehicle while ensuring a certain strength.

4. General engineering field: For example, fan, water pump, auto parts, chemical pipes and other products, 6063 large diameter aluminum tube is suitable for these fields due to its good oxidation resistance, corrosion resistance and impact resistance, as well as its ability to withstand high pressure and high temperature.

5. Electronic and electrical field: With its good conductivity and corrosion resistance, it can be used to make radiators, electronic casings, etc.

6. Aerospace field: Although its strength is not as good as some higher specification aluminum alloys, it may also be used in some non-critical parts or parts with stricter weight requirements.

| Item | Aluminum pipe/pipes Aluminium Tube/Tubes/tubing | |

|---|---|---|

| Material | Aluminum | |

| Grade | 1000 series: 1050,1060,1070,1080,1100,1435, etc 2000 series: 2011,2014,2017,2024, etc 3000 series: 3002,3003,3104,3204,3030, etc 5000 series: 5005,5025,5040,5056,5083, etc 6000 series: 6101,6003,6061,6063,6020,6201,6262,6082, etc 7000 series: 7003,7005,7050,7075, etc |

|

| standards | ASTM, ASME,EN, JIS, DIN,GB/T etc | |

| Size | Outer Diameter:3-250mm | |

| Wall Thickness: 0.3-50mm | ||

| Length: 10mm -6000mm | ||

| Surface treatment | Mill finishAnodizedElectrophoresisPowder coatingWooden grainSandblast | |

| Surface colors | Nature, silver, bronze, champagne, black, golden, etcAs customized | |

| Temper | T3-T8 | |

| MOQ | 1 Ton | |

| Molding/Pattern | 1. Using our molds, no fee 2. Using customer drawing, opening mold, usually about 5 tons the molding fee is free. 3. Can be discussed. |

|

| Application | 1. Lighting, solar reflector plate. 2.architectural appearance, interior decoration:ceiling,metope,furniture,cabinets and so on. 3.elevator,nameplate, bags. 4.automotive interior and exterior decoration. 5. Interior decoration: such as photo frame. 6.household appliances, refrigerator, microwave oven, audio equipment. 7. Aerospace and military aspects. 8, machinery parts processing, mold manufacturing. 9. chemical/insulation pipeline coating. |

|

| Container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)24-26CBM | |

| 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 54CBM | ||

| 40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) 68CBM | ||

| MOQ | 1 Ton | |

| Temper | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38 H114/H194, etc. | |

| Specification | Thickness≤30mm; Width≤2200mm Length≤12000mm OR Coil (C) | |

| Application | Decoration, heat-sink device, external walls, storage, sheets for construction, etc. | |

| Feature | Good rust resistance, not suitable for heat treatments, good corrosion resistant | |

| performance, well welding property, good plasticity, low strength but suitable | ||

| for cold working hardening | ||

It has good plasticity and machinability, capable of meeting the needs of various complex shapes and structures. – Its electrical conductivity is 55-63% IACS. – Density is 2.69g/cm ³.

The main alloying elements are magnesium (Mg) and silicon (Si), and the main strengthening phase is Mg -2 Si. – The other elements contained are usually: silicon Si content 0.20-0%, iron Fe content ≤ 0.35%, copper Cu content ≤ 0.10%, manganese Mn content ≤ 0.10%, magnesium Mg content 0.45-0%, zinc Zn content ≤ 0.10%, titanium Ti content ≤ 0.10%, chromium Cr content ≤ 0.10%, single impurity content ≤ 0.05%, total impurity content ≤ 0.15%, and the balance is aluminum Al.

Standard shipment package

plenty inventory

international standard

24 hours 7 days online

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.

14# Shenglung Building, Heping West road, Xinhua District, Shijiazhuang City, China

+(86) 19353265952

Don’t miss our future updates! Get Subscribed Today!