- +86 19353265952

- [email protected]

- Shijiazhuang city

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

7075 aluminum alloy rod is a kind of high strength alloy material. Contains copper, zinc, magnesium and other elements, high strength and hardness. Widely used in aerospace, military, sporting goods and other fields, such as aircraft parts, sports equipment, etc. Excellent performance, but the processing difficulty is relatively large and the price is high.

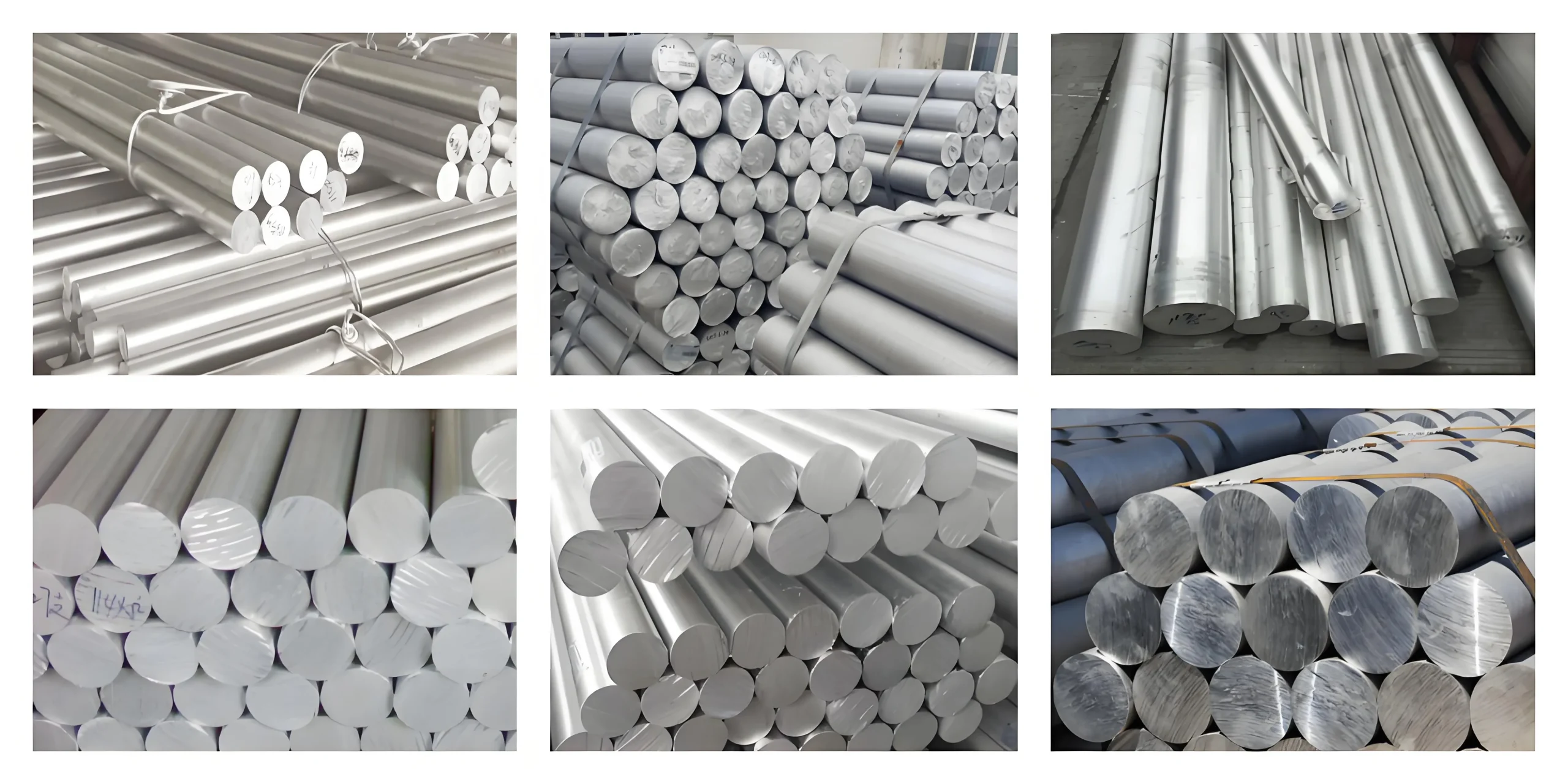

Category: 7075 Aluminum Rod

Key word: 7075 Aluminum Rod

![]() Whatsapp :+86 19353265952

Whatsapp :+86 19353265952

![]() Email : [email protected]

Email : [email protected]

1.Aerospace field :

It is often used in the manufacture of aircraft structural parts, such as wing truss strips, fuselage frames, landing gear, etc., which can reduce the weight of aircraft and ensure structural strength.

2. Military industry field :

It can be used to manufacture parts of weapons and equipment, such as missile parts, armored vehicle structural parts, etc.

3. Sporting goods :

For example, high-grade bicycle frames, golf club heads, skis, etc., its high strength can meet the performance requirements of sports equipment.

4. Mold manufacturing :

Structural parts used as molds, which can withstand greater pressure and wear.

5. Mechanical manufacturing : Such as the key parts of the manufacturing machinery such as shafts, gears, etc.

| Item | Aluminium bar ,Aluminium rod, Aluminium alloy bar, Aluminium alloy rod |

|---|---|

| Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc |

| Grade | 1000, 2000, 3000, 4000, 5000, 6000series a) 1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc. b) 2000 Series: 2014, 2024, etc. c) 3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc. d) 4000 Series: 4045, 4047, 4343, etc. e) 5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5454, 5754, 5A06, etc. f) 6000 Series: 6061, 6063, 6082, 6A02, etc. |

| Length | <6000mm |

| Diameters | 5-590mm |

| Temper | 0-H112,T3-T8, T351-851 |

| Surface | mill, bright, polished, hair line, brush,sand blast, checkered,embossed, etching,etc |

| MOQ | 1 Ton |

| Aplication | 1)Further making utensil2)Solar reflective film3)The appearance of the building 4)Interior decorating; ceilings, walls,etc5)Furniture cabinets6)Elevator decoraction 7)Signs, nameplate,bags making8)Decorated inside and outside the car 9)Household appliances:refrigerators, microwave ovens, audio equipment,etc |

– Tensile strength: 524Mpa – 0.2% Yield strength: 455Mpa – Elongation: 11% – Elastic modulus E: 71GPa – Hardness: 150HB – Density: 2.81g/cm ³ – Coefficient of thermal expansion (20-100 ° C): 23.6 um/m · k – Melting point range: 475-635 ° C – Conductivity 20 ° C (68 ° F): 33% IACS – Resistivity 20 ° C (68 ° F): 0.0515 m ²/m

Silicon (Si): 0.40% – Iron (Fe): 0.50% – Copper (Cu): 1.2-2% – Manganese (Mn): ≤ 0.30 % -Magnesium (Mg): 2.1-2% -Chromium (Cr): 0.18-0% -Zinc (Zn): 5.1-6% -Titanium (Ti): ≤ 0.20% -Aluminum (Al): Balance 7075 Aluminum alloy is a cold-treated forging alloy with high strength, good mechanical properties and anodic reaction. It is one of the most powerful alloys commercially available. The fine grains allow for better deep drilling performance, enhanced tool wear resistance, and more distinctive thread rolling.

Standard shipment package

plenty inventory

international standard

24 hours 7 days online

Our factory manufactures a comprehensive array of steel products, including but not limited to, structural beams, steel bars, plates, and coils. We also offer bespoke solutions catering to specific dimensions and compositions as per customer requirements.

Absolutely, all our steel products adhere to international standards and undergo rigorous quality assurance tests. We hold various certifications, including ISO 9001, emphasizing our commitment to quality. Each product batch comes with a certification detailing its grade and compliance standards.

Yes, we are equipped to manage significant order volumes even within constrained timelines, thanks to our advanced operational processes, sizable workforce, and efficient logistics network. However, we always suggest contacting us with specifics as early as possible for the best outcomes.

Sustainability is at the core of our operations. We utilize energy-efficient technologies, recycle scrap material, and follow strict environmental protocols to minimize our ecological footprint. Our commitment extends beyond compliance, aiming for a future-focused, sustainable approach in all we do.

Worker safety is paramount. Our factory complies with all health and safety regulations, providing regular training, enforcing strict on-site protocols, and equipping our staff with advanced safety gear. We believe a safe worker is an empowered worker.

Certainly. We pride ourselves on our capability to provide tailored solutions. Our team of experts collaborates closely with clients to understand their needs, offering custom compositions, cuts, and finishes unique to their project demands.

We manage logistics through trusted partners, ensuring timely and safe deliveries. Customers receive tracking information once orders are dispatched and can monitor their shipment in real-time. Additionally, our customer service team is always on standby to assist.

We stand by the quality of our products. In the rare instance of defects or non-compliance, we have a transparent return or exchange policy. Clients are encouraged to reach out within a specified period after receipt, and we promise a swift, fair resolution in line with our terms and conditions.

14# Shenglung Building, Heping West road, Xinhua District, Shijiazhuang City, China

+(86) 19353265952

Don’t miss our future updates! Get Subscribed Today!